Custom Pump Controls

-

Simplex, duplex, triplex pump control and more

-

Pump control using conventional motor starters or high-efficiency VFDs

-

PLC or relay-based logic

-

Level or flow control

-

Temperature monitoring

-

Seal leak monitoring

NE152

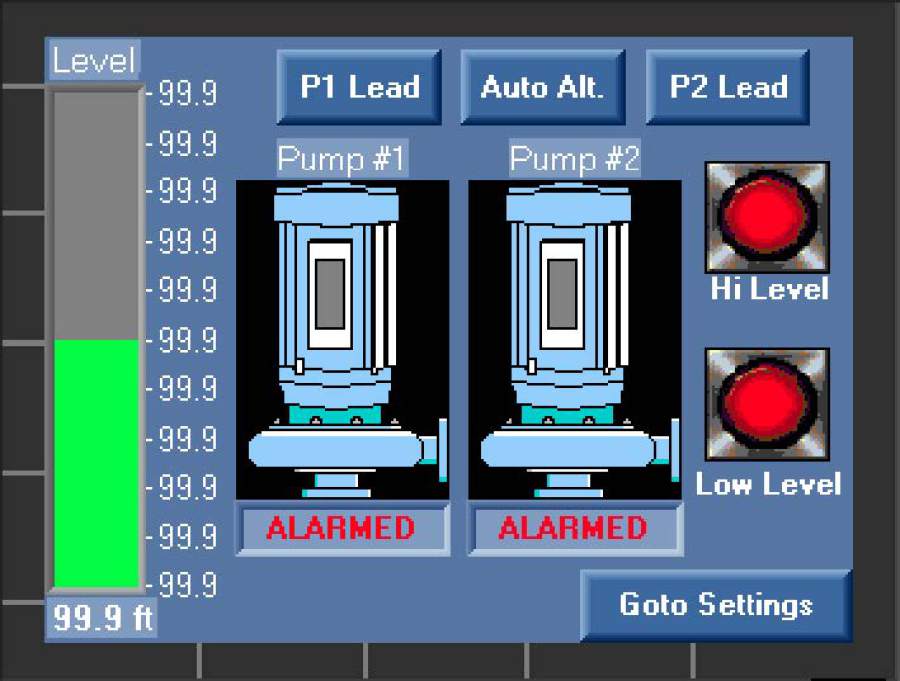

The NE152 has been designed and engineered to be a direct replacement for the US Filter D152 pump controller.

Features include:

- Fits the D152 cutout for easy replacement in the field

- Utilizes a touch screen color display for setpoints, indication of pump status, and well level

- Simple and intuitive control

- Provides fixed lead/lag and alternation on each cycle

- High and Low (Abnormal) level alarm in response to a 0-10 volt DC or 4-20mADC level-proportional signal as provided by an external sensor (e.g. submersible level transducer, ultrasonic level transmitter or any other sensor that produces a linear, level-proportional analog output)

- Normally open contacts for each pump call to run

- Form C contact for alarm outputs

Click to download the full manual for the NE 152 Duplex Pump Controller

NE152 MANUAL.pdf

Adobe Acrobat document [309.5 KB]

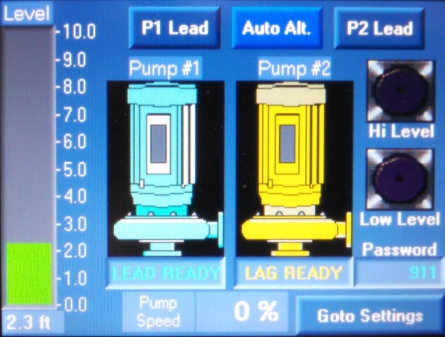

NE250

The NE250 was designed and engineered to replace select functions of the Intralink LC150 pump controller.

Features include:

- Fits the LC150 cutout for easy replacement in the field

- Utilizes a touch screen color display for setpoints, indication of pump status, and well level

- Simple and intuitive control of a duplex pump system using VFDs

- Provides fixed lead/lag or alternation on each cycle

- High and Low (Abnormal) level alarm in response to a 0-10 volt DC or 4-20mADC level-proportional signal as provided by an external sensor (e.g. submersible level transducer, ultrasonic level transmitter or any other sensor that produces a linear, level-proportional analog output)

- Available float control and alarms

- Normally open contacts for each pump call to run

- Two available analog outputs for VFD speed control

- Form C contact for alarm outputs

Click to download the NE250 Cut Sheet

NE 250 Info Page Rev3.pdf

Adobe Acrobat document [261.1 KB]

Click to download the full manual for the NE 250 Variable Speed Duplex Pump Controller

NE250 Manual Rev3.pdf

Adobe Acrobat document [689.6 KB]

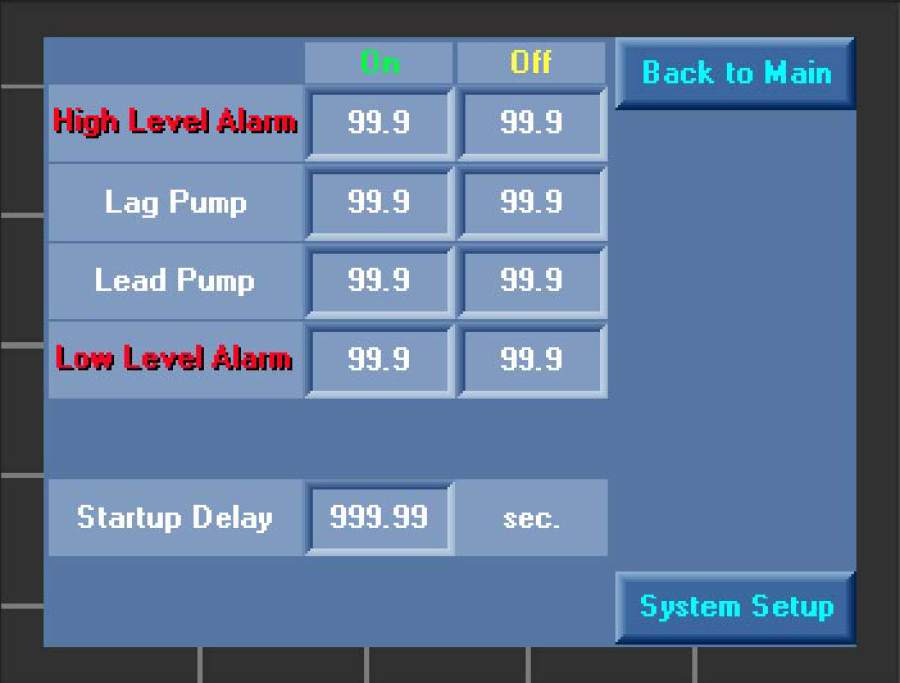

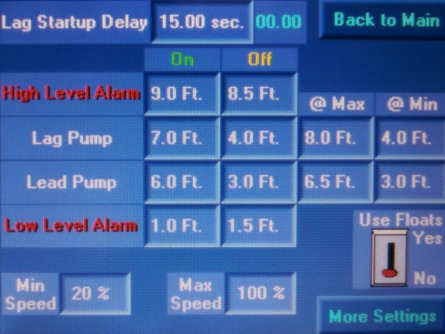

NE250 Settings Screen

From the Settings Screen, you can adjust your alarm and pump control level setpoints. This screen is also used to set the minimum and maximum speed for use with VFDs and whether the system is using back up floats.

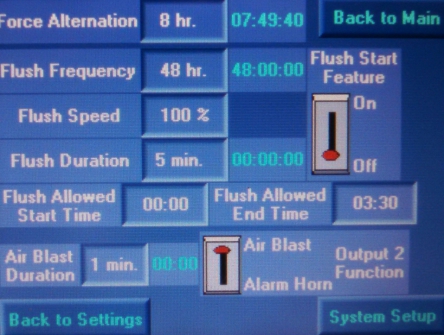

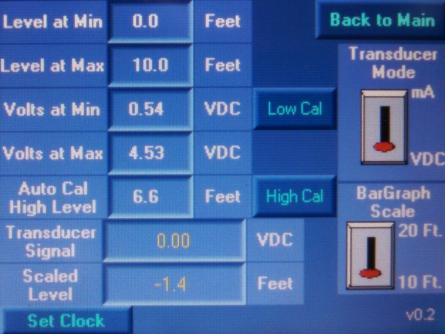

NE250 System Setup Screen

This screen is used to scale the transducer input and the bargraph on the Main Screen.